Recommendations for stripping the various types of substrate

using Underwater Systems products

The surfaces must be thoroughly degreased and free of any sanding residue before application.

Steel

Degrease the surface with PROFESSIONAL DEGREASER and remove any corrosion using standard sandblasting (Sa 2 1/2). If sandblasting is not an option, sand back the metal surface using a grade 24-36 up to St3 surface preparation standard with a 50-75 surface roughness. Eliminate all sanding residue from the surface. Clean thoroughly, leave to dry and carefully apply our PROFESSIONAL EPOXY PROTECT or PROFESSIONAL PRIMER PROTECT according to the technical specifications and technical data sheets.

Aluminium

Degrease the surface with PROFESSIONAL DEGREASER and sand back using a grade 60-120 abrasive compatible with aluminium. Eliminate all sanding residue from the surface. Clean and leave to dry, then carefully apply our PROFESSIONAL EPOXY PROTECT primer as soon as possible (within 8 hours), according to the technical specifications and technical data sheets.

Gelcoat, epoxy, carbon fibre

Degrease the surface with PROFESSIONAL DEGREASER, sand back using a grade 180-220 abrasive. Eliminate all sanding residue from the surface. Clean, leave to dry and carefully apply our PROFESSIONAL EPOXY PROTECT primer according to the technical specifications and technical data sheets.

Wood

Degrease using PROFESSIONAL DEGREASER, sand back using a grade 80 -180 abrasive and eliminate all sanding residue from the surface. Degrease again with PROFESSIONAL DEGREASER and leave to dry completely. When perfectly dry, carefully apply our PROFESSIONAL EPOXY PROTECT or PROFESSIONAL PRIMER PROTECT according to the technical specifications and technical data sheets.

Bronze

Degrease the surface with PROFESSIONAL DEGREASER then lightly sand back with a grade 80 abrasive until the metal becomes white (be careful not to modify the propeller profile). Eliminate all sanding residue from the surface. Clean, leave to dry and carefully apply our PROFESSIONAL EPOXY PROTECT primer according to the technical specifications and technical data sheets.

Lead

Degrease with PROFESSIONAL DEGREASER, then sand back with a grade 120 abrasive or a rotating brush. Eliminate all sanding residue from the surface. Clean, leave to dry and carefully apply our PROFESSIONAL EPOXY PROTECT or PROFESSIONAL PRIMER PROTECT according to the technical specifications and technical data sheets.Suggested formulas for underwater zones

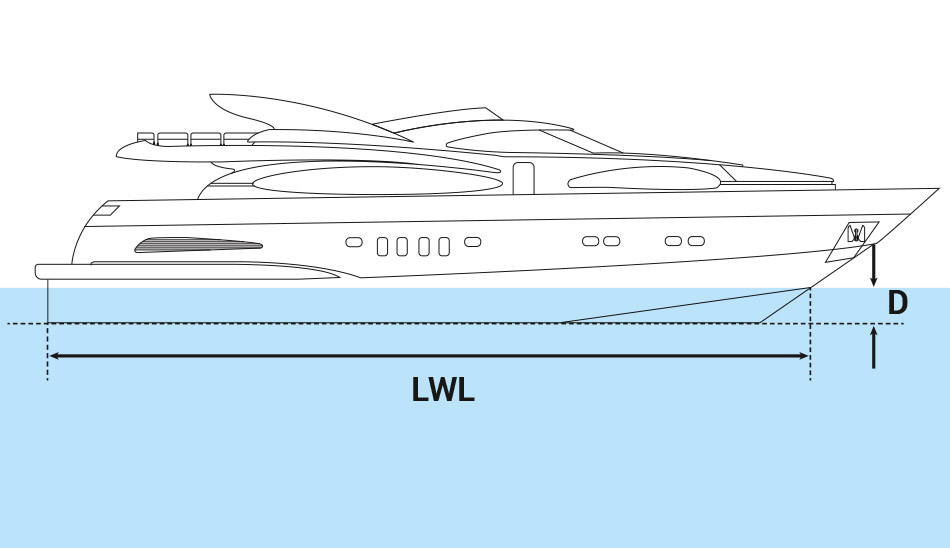

How much product do you need?

Motor yacht

LWL x (B + D) = Underwater surface area (m2)

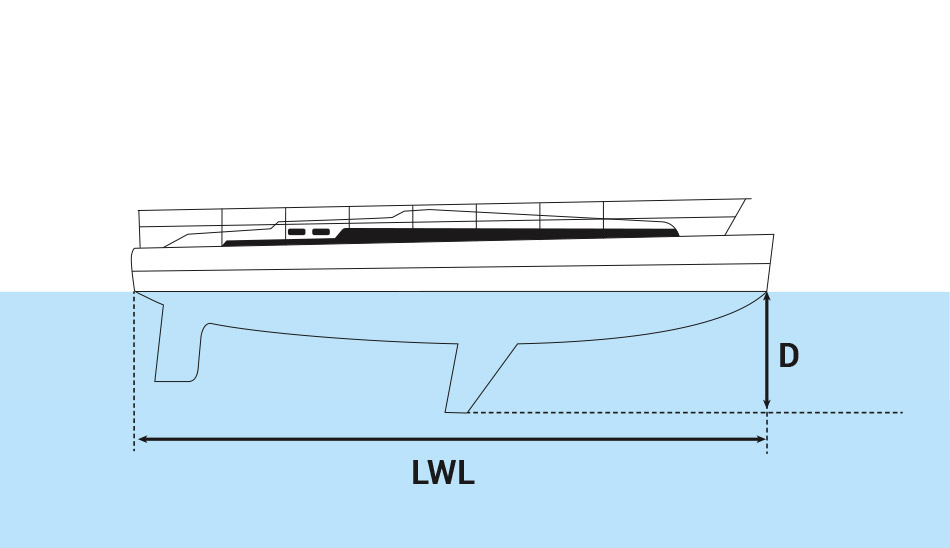

Narrow keel yacht

0.50 x LWL x (B + D) = Underwater surface area (m2)

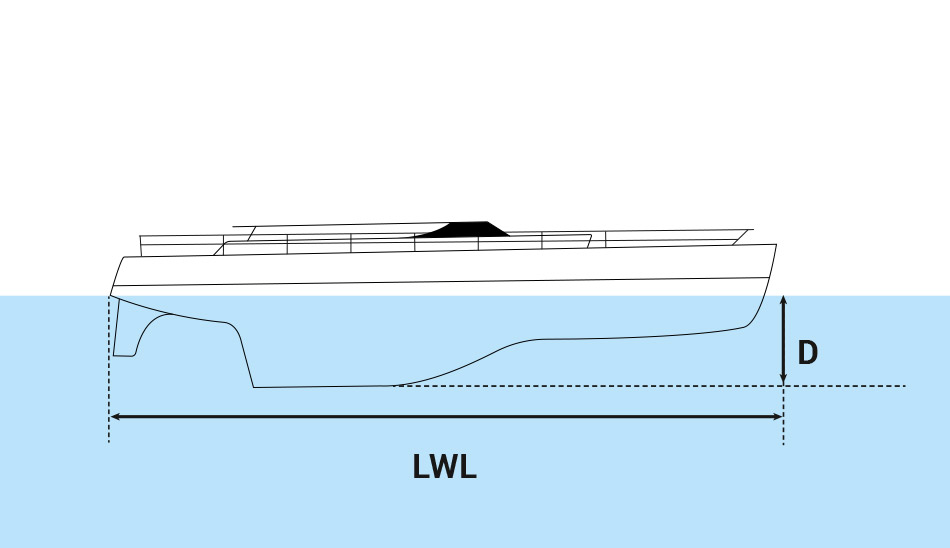

Long keel yacht

0.75 x LWL x (B + D) = Underwater surface area (m2)

| LWL | Length at waterline |

| B | Beam |

| D | Draught |